Who We Are

Sky Tech is a precision-driven CNC machining company based in Chennai, delivering high-accuracy components for demanding industrial applications.

Built on strong engineering fundamentals and modern manufacturing practices, we specialize in CNC milling, turning, and VMC-based production with a focus on tight tolerances, superior finish, and consistent quality.

With the ability to machine both standard and high-performance alloys, we support customers across Automotive, Oil & Gas, and General Manufacturing sectors.

Every component we produce reflects our commitment to engineering discipline, process control, and customer reliability.

We don’t just manufacture parts — we manufacture confidence.

Edge-to-Edge Craftsmanship

Precision begins from the very first setup and continues until the final inspection.

Every machining operation is executed with strict attention to dimensions, surface finish, and geometric accuracy.

Our operators follow standardized machining practices, ensuring tool stability, proper cutting parameters, and controlled setups for repeatable results.

We believe great parts are not made by shortcuts — they are built through skill, discipline, and consistency at every step of the manufacturing process.

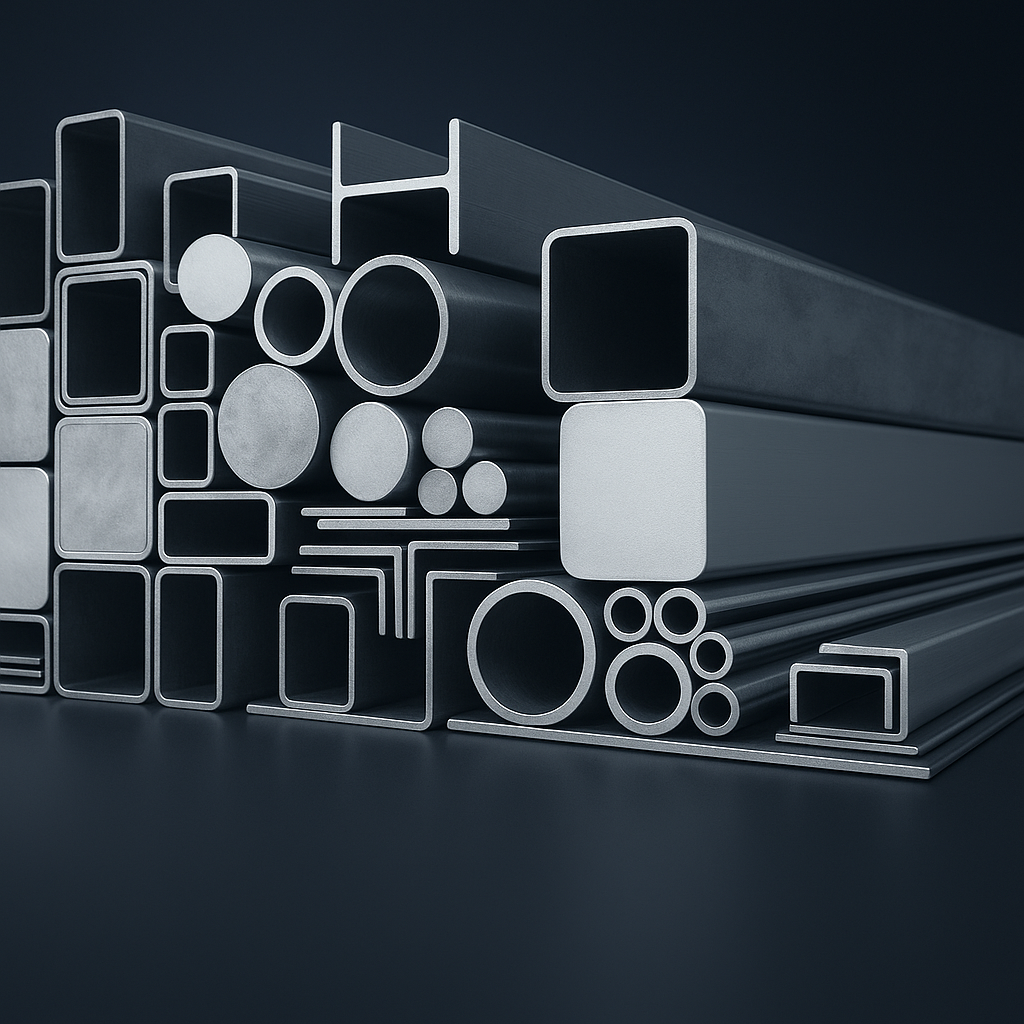

Material Intelligence

Different materials behave differently under machining — and we understand that deeply.

From stainless steels and alloy steels to aluminium, brass, Inconel, and Duplex grades, we apply the right cutting strategies, tooling selection, feeds, speeds, and cooling methods for each material.

This material-focused approach results in:

- Better surface finish

- Longer tool life

- Dimensional stability

- Improved part performance in real-world applications

We don’t just cut metal — we engineer how it is cut.

Closed-Loop Quality

Quality at Sky Tech is built into the process, not added at the end.

Every stage of production is monitored through a closed-loop quality system that connects machining, inspection, correction, and verification.

Key quality practices include:

- Inspection of Incoming Materials

- Precision 2D height gauge inspection

- Material traceability using heat number tagging

- Final dimensional inspection and Verification of the product before dispatch

This disciplined approach ensures that what is designed, machined, inspected, and delivered always matches customer specifications — without compromise.