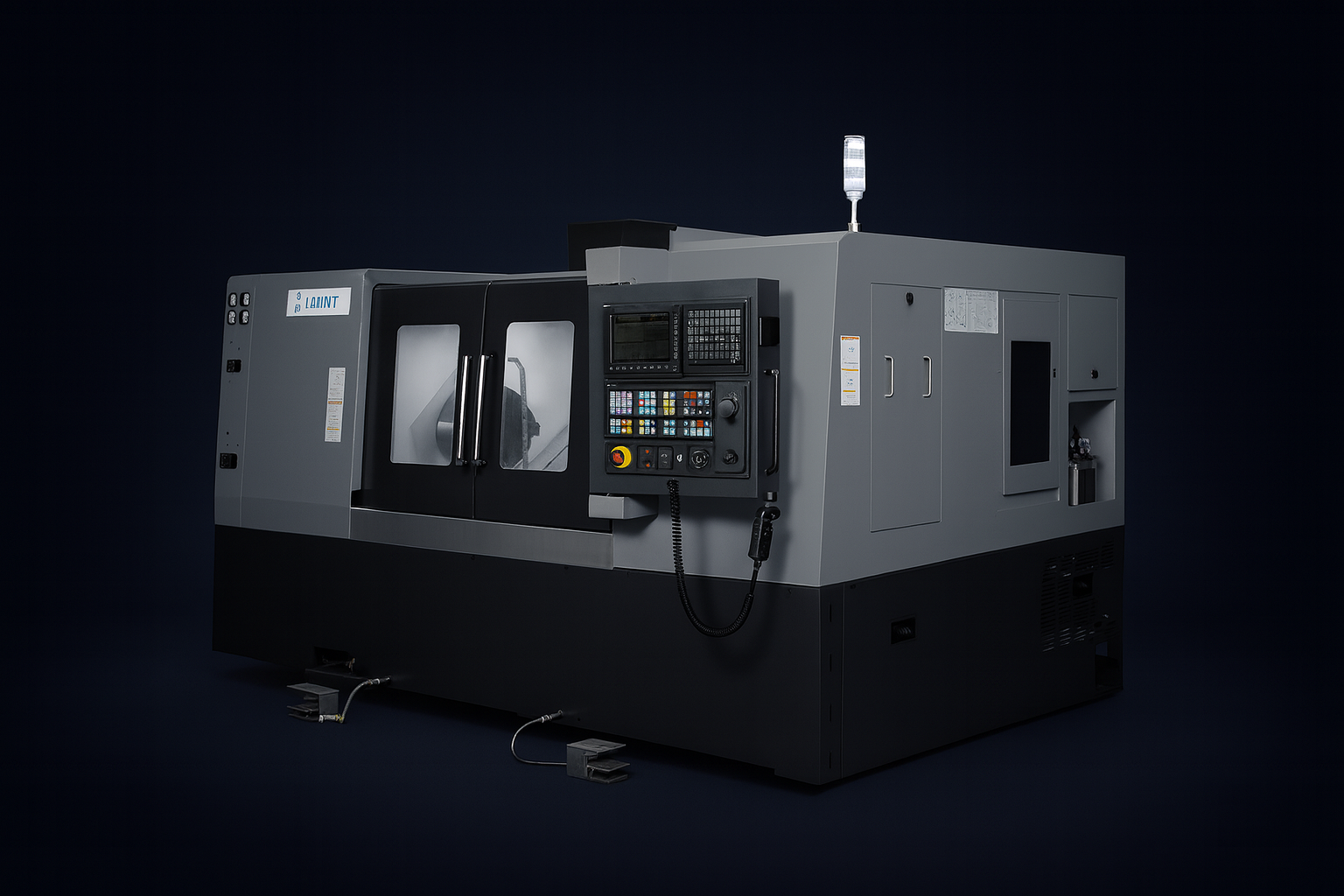

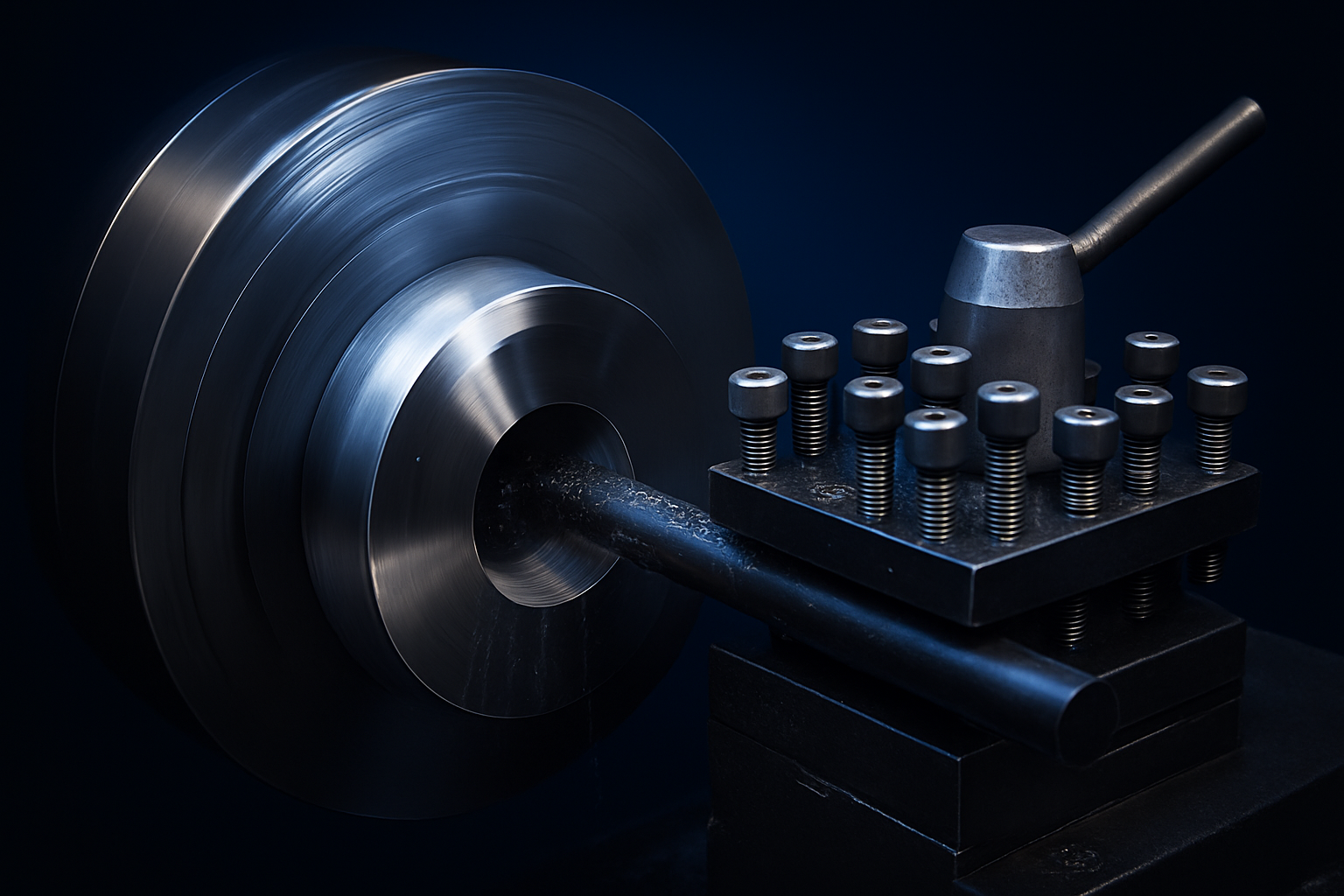

LMW LL30TL7 – Heavy-Duty CNC Turning Center

High-rigidity turning center for medium to heavy-duty applications requiring high material removal, tight diameter control, excellent

cylindricity, and smooth surface finishes.

Applications

- Shafts & transmission components

- Bushings & sleeves

- Flanges & collars

- Threaded mechanical parts

Key Technical Strengths

- High spindle torque for hard materials

- Excellent chip evacuation for continuous production

- Stable cutting performance on alloy steels & stainless steels

- Roughing and finishing in a single setup

Delivers tight diameter tolerances, excellent concentricity, and repeatability across large batches.

LMW LL20T5 – High-Precision Compact Turning Center

Optimized for small to medium precision components where dimensional stability is critical; ideal for tight-tolerance production.

Applications

- Precision spacers

- Instrument components

- Small bushings

- Threaded inserts

- Automotive precision parts

Key Technical Strengths

- High-repeatability servo control

- Excellent control over fine finishing cuts

- Low vibration for micron-level accuracy

- Ideal for clean surface finish and exact fits

Enables consistent batch accuracy for small, high-value components.

Batliboi Sprint 25TC-LX – Industrial Production Turning Center

Production-grade CNC lathe built for robust turning where productivity and consistency are critical.

Applications

- Automotive turned parts

- Valve components

- Hydraulic fittings

- Industrial fasteners

- General engineering turned parts

Key Technical Strengths

- High structural rigidity for heavy cutting

- Long continuous running capability

- Stable thermal behavior for dimensional consistency

- Excellent performance on carbon and alloy steels

Backbone for high-volume turning with minimal dimensional drift.

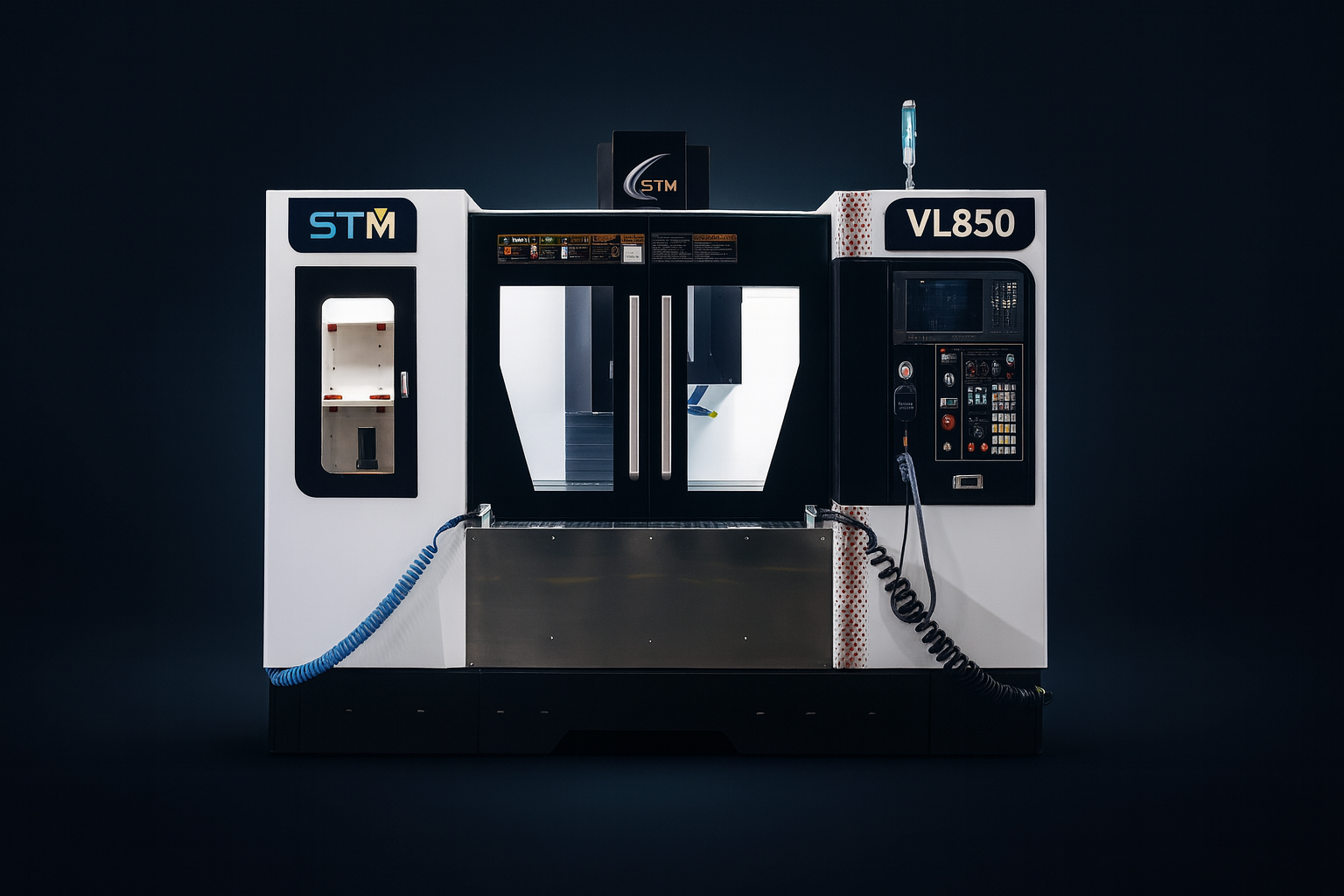

STM VL850 – Precision Vertical Machining Center

High-accuracy VMC for complex milling, profile machining, and precision hole-making.

Applications

- Brackets & mounting plates

- Housings & enclosures

- Manifolds

- Structural components

- Jigs & fixtures

Key Technical Strengths

- High spindle accuracy for fine milling

- Stable axis movement for pocketing and contouring

- Reliable drilling, tapping, and profiling performance

- Ideal for stainless steel, aluminium, EN materials, and brass

Delivers accurate 3-axis milling with consistent dimensional control and excellent edge finish.

STM VL1050 – Large Capacity Vertical Machining Center

Larger-bed, high-load VMC for bigger, heavier components requiring structural stability during machining.

Applications

- Base plates

- Heavy structural brackets

- Energy-sector components

- Large housings

- Multi-operation industrial parts

Key Technical Strengths

- High load-handling capacity

- Strong column structure for vibration-free cutting

- Excellent accuracy during heavy material removal

- Multi-stage machining capability in one setup

Handles large components with precision, reducing setup errors and turnaround time.

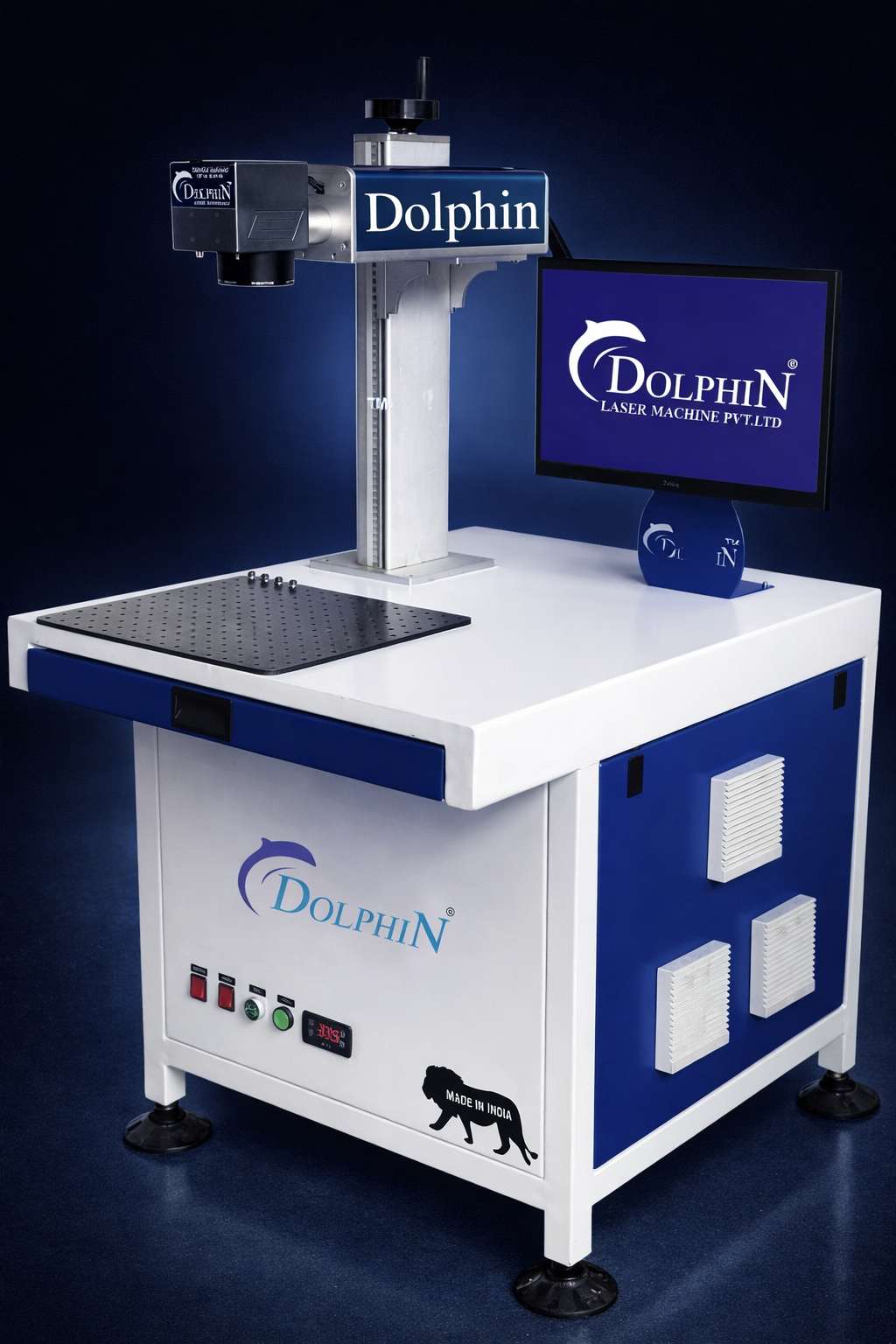

Dolphin Fiber Laser Marking Machine – A high-precision fiber laser system

Engineered for permanent, high-contrast marking on metal components where accuracy, consistency, and traceability are critical; Ideal for industrial identification and branding applications.

Applications

- Serial numbers and UID marking

- QR codes and barcodes

- Tool and die identification

- Automotive and engineering parts

- Nameplates and logos

Key Technical Strengths

- High-speed, contact-free laser marking

- Micron-level precision with repeatable accuracy

- Clean, distortion-free engraving on metals

- Low maintenance and long operational life

Enables reliable, permanent marking for precision-driven manufacturing environments.

Digital Height Gauge – Precision Measurement System

Engineered for precise height, step, and reference measurements where dimensional accuracy and repeatability are critical; ideal for quality inspection and tool room environments.

Applications

- Component height measurement

- Step and depth inspection

- Datum setting and layout marking

- Tool room and QC inspection

- Precision part verification

Key Technical Strengths

- High-resolution digital readout for accurate measurements

- Smooth vertical guideway for stable, repeatable results

- Rigid construction for minimal measurement error

- User-friendly control panel for efficient inspection

Ensures reliable and consistent measurement for precision-driven manufacturing and quality control.

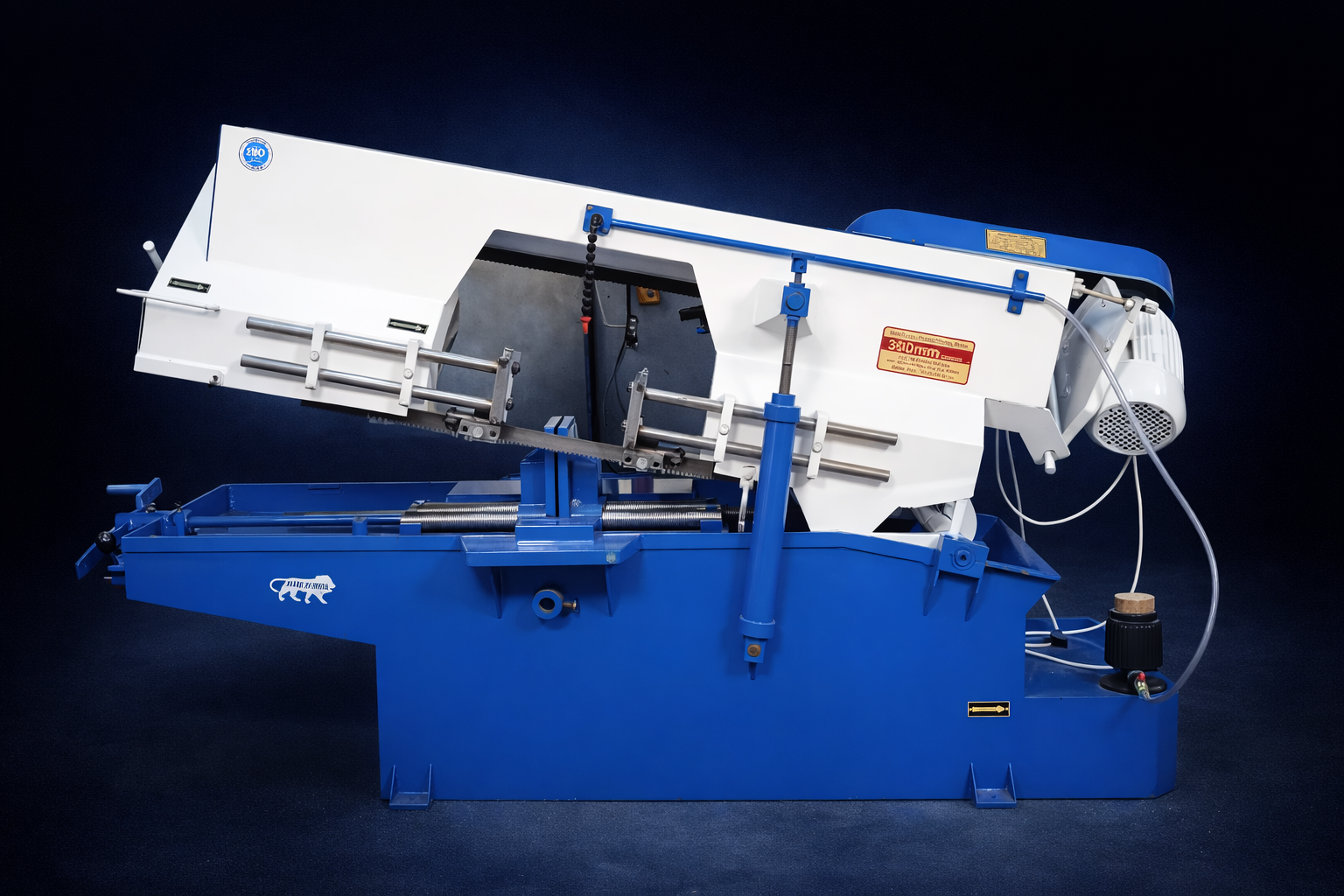

Metal Cutting Bandsaw – Industrial Cutting System

Designed for high-efficiency cutting of mild steel and metal profiles where speed, consistency, and cut accuracy are critical; ideal for fabrication shops and production units.

Applications

- Cutting rods, bars, and pipes

- Structural steel section cutting

- Batch cutting for fabrication lines

- Workshop and industrial metal processing

- Precision length cutting operations

Key Technical Strengths

- Automatic horizontal cutting operation

- Rigid frame for vibration-free cutting

- Consistent cut accuracy and surface finish

- Suitable for continuous industrial use

Delivers reliable, high-throughput metal cutting for demanding industrial applications.

Overall Manufacturing Capability

- CNC Turning (Small, Medium & Heavy Components)

- CNC Milling (3-Axis & Multi-Operation)

- Medium to High-Volume Batch Production

- Stainless Steel, Alloy Steel & Exotic Metal Machining

- Tight Tolerance Control up to ±0.01 mm

- Complex Profile & Heavy Structural Part Manufacturing

Inspection & Dimensional Verification

- 2D height gauge inspection

- In-process dimensional checks

- Final-stage dimensional verification

- Material traceability with heat number tagging

This ensures that what is machined is exactly what is delivered.