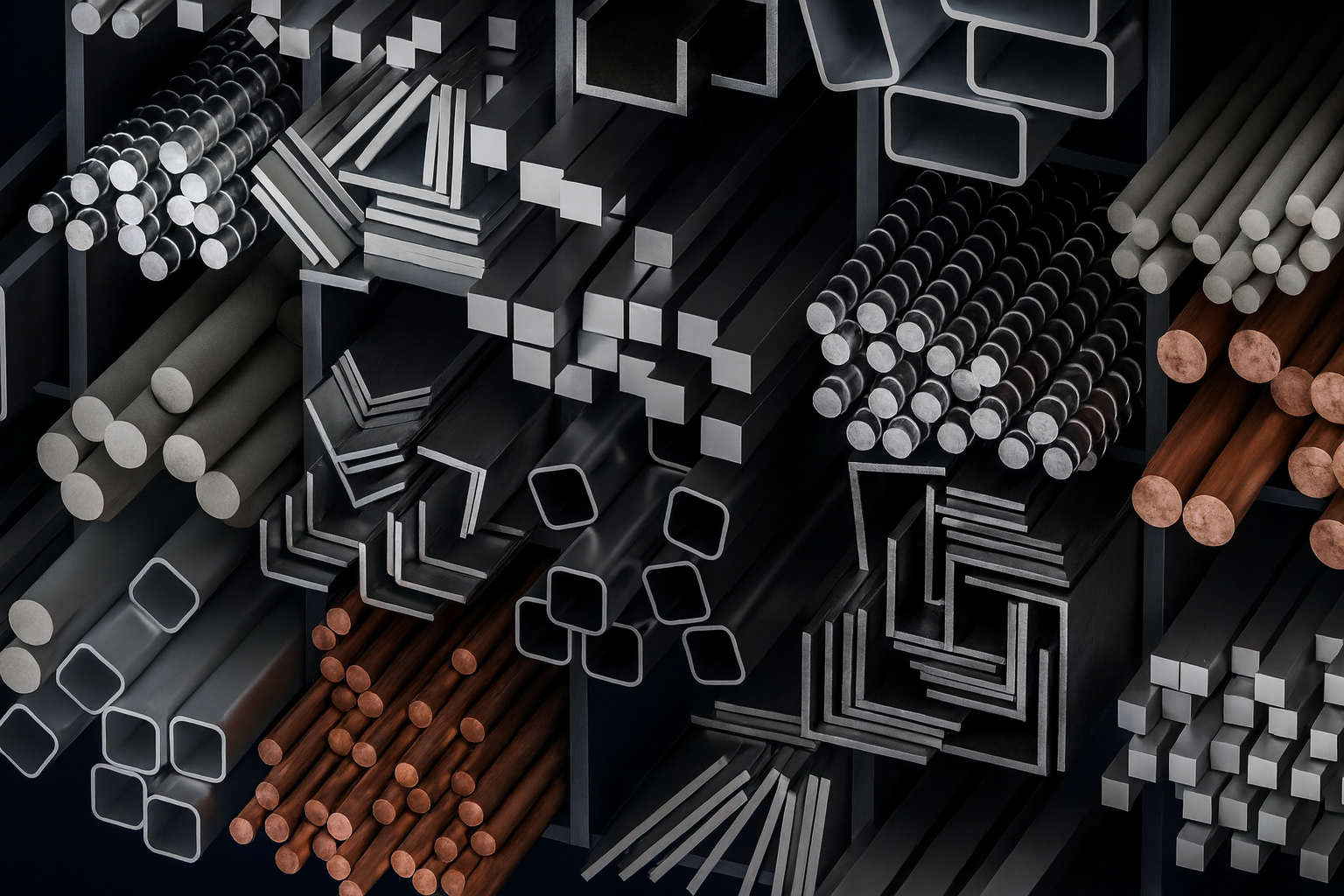

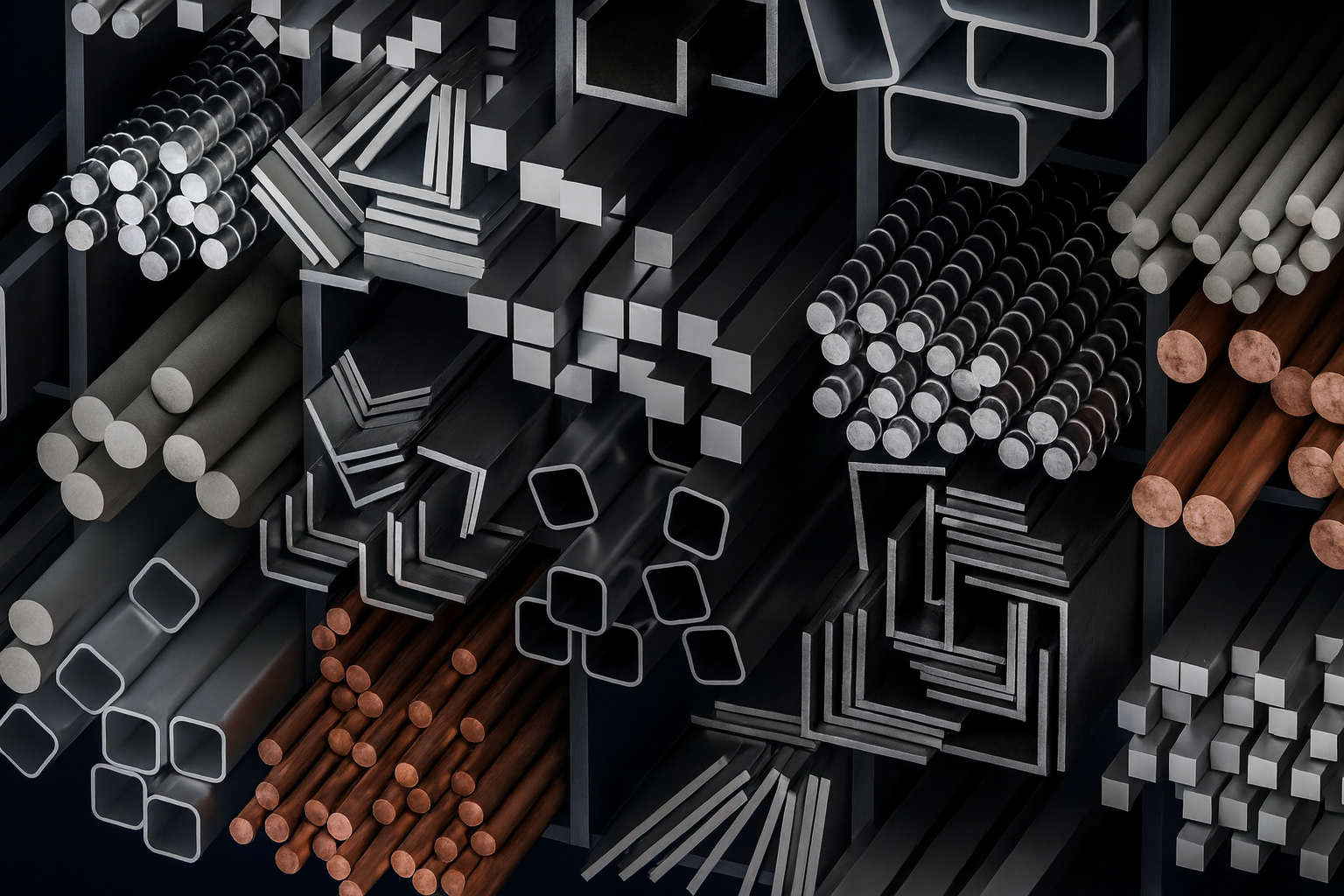

Materials We Machine

We specialize in machining both standard and exotic metals used in demanding industrial environments. Our material expertise allows us to

optimize tooling, cutting strategies, and finishing methods for each grade.

Stainless Steels

Used for corrosion resistance, hygiene-critical applications, and structural durability.

Alloy & Carbon Steels

Chosen for high strength, wear resistance, and load-bearing performance.

High-Performance & Exotic Alloys

- Inconel

- Duplex

- Super Duplex

Used in extreme temperature, pressure, and corrosive environments—especially in Oil & Gas and heavy engineering sectors.

Non-Ferrous Metals

Ideal for lightweight applications, electrical components, precision fittings, and decorative or wear-resistant parts.

Machining Tolerance Capability

Sky Tech delivers precision machining with a typical tolerance capability of ±0.01 mm. This ensures:

- Accurate part fitment

- Reliable assembly performance

- Reduced rework and rejection

- Complete dimensional consistency across batches

Our tolerance control is supported by:

- Stable CNC machining processes

- Optimized cutting parameters

- Controlled tooling systems

- Regular in-process and final inspection

Surface Finish & Dimensional Stability

Beyond tight tolerances, we focus on:

- Smooth surface finish

- Burr-free edges

- Stable geometry

- Consistent dimensional behavior after secondary processing

This ensures components perform exactly as intended in real application environments.

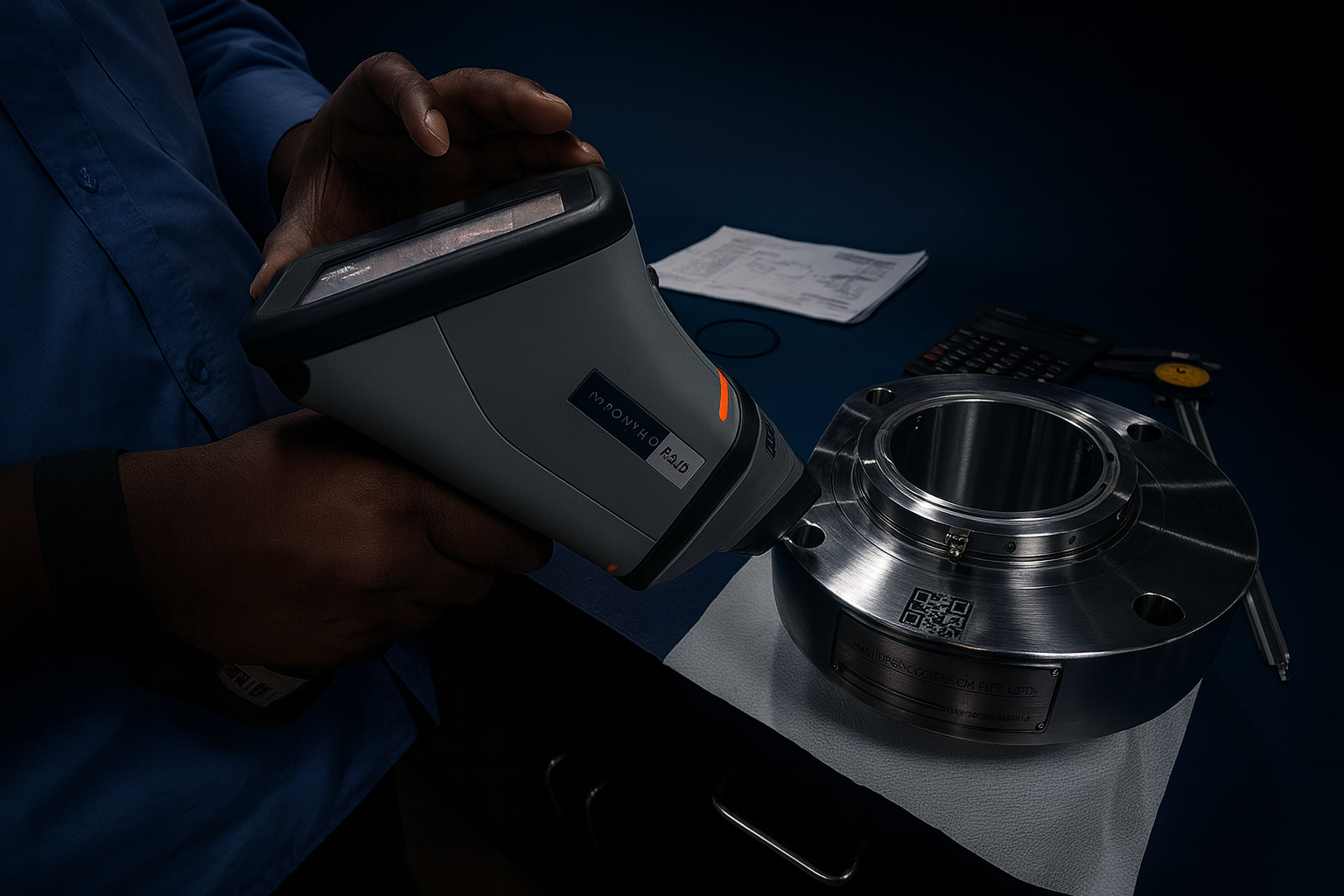

Material Traceability & Verification

Every critical component we machine is supported with material traceability using heat number tagging. This ensures:

- Verified raw material authenticity

- Complete production history tracking

- Compliance with customer documentation requirements

- Full accountability through the supply chain

Why Our Material & Tolerance Control Matters

- Enables high-precision mechanical assemblies

- Prevents premature wear and failure

- Ensures safety in pressure and load-bearing systems

- Guarantees repeatability for mass production

- Improves product life and performance