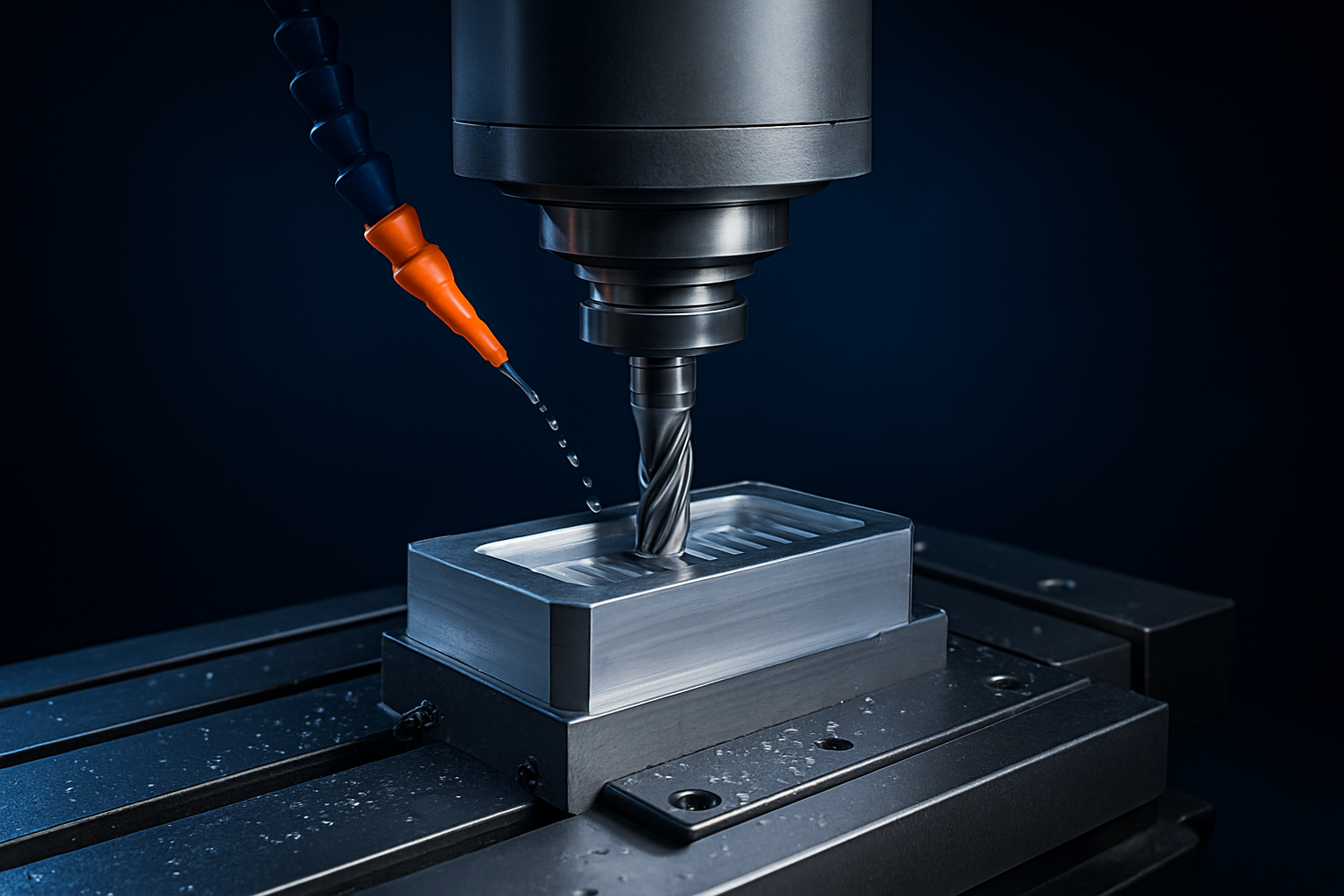

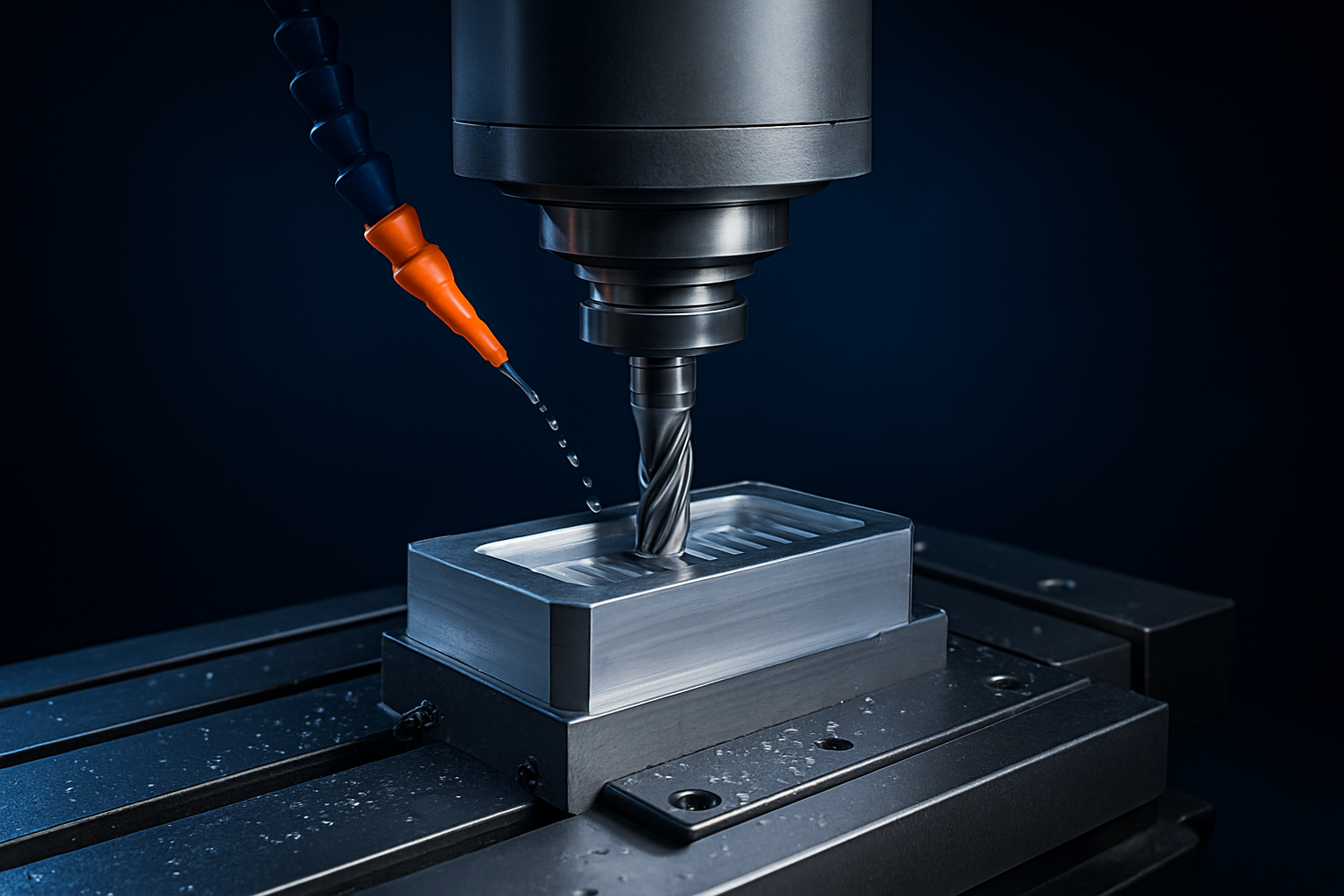

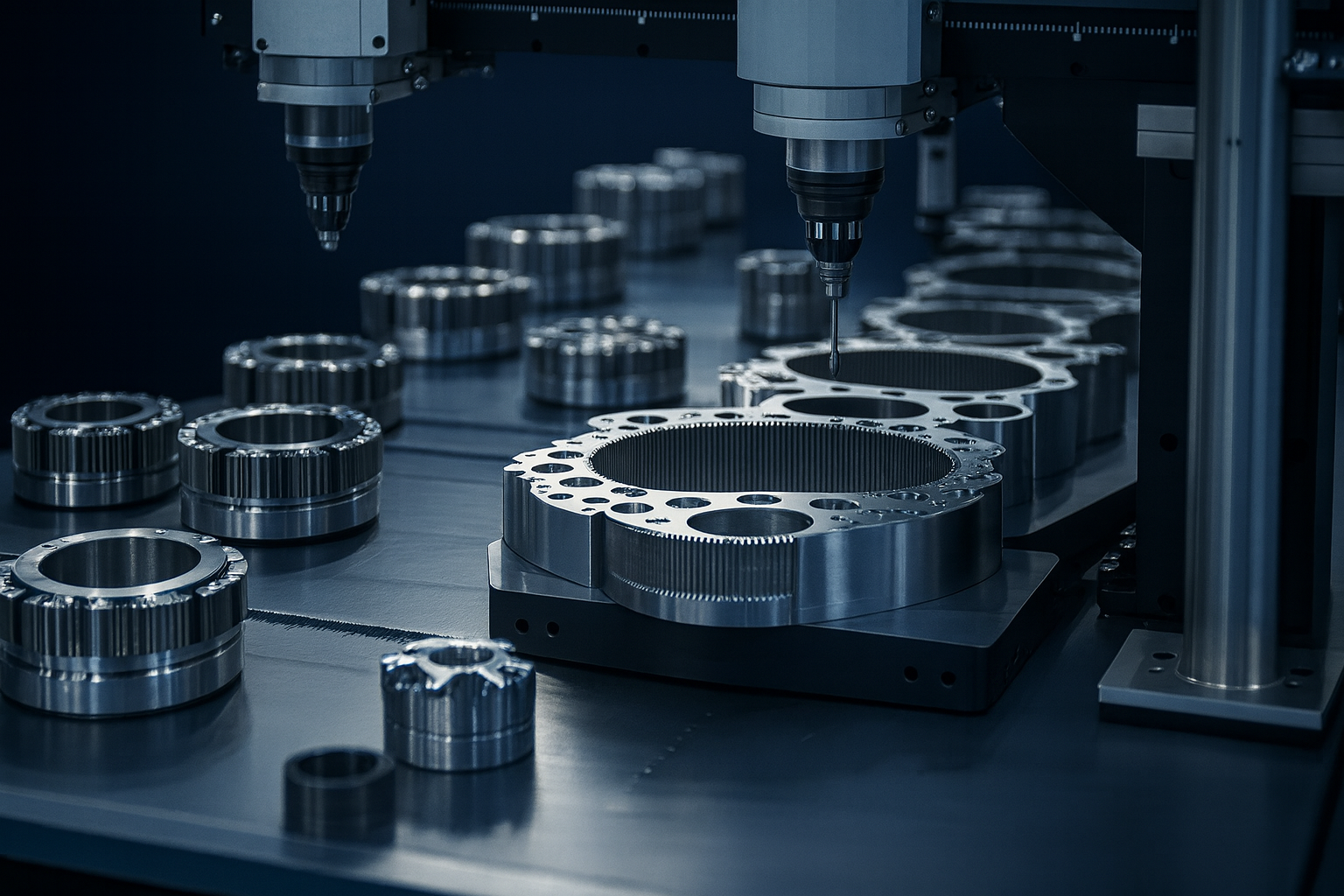

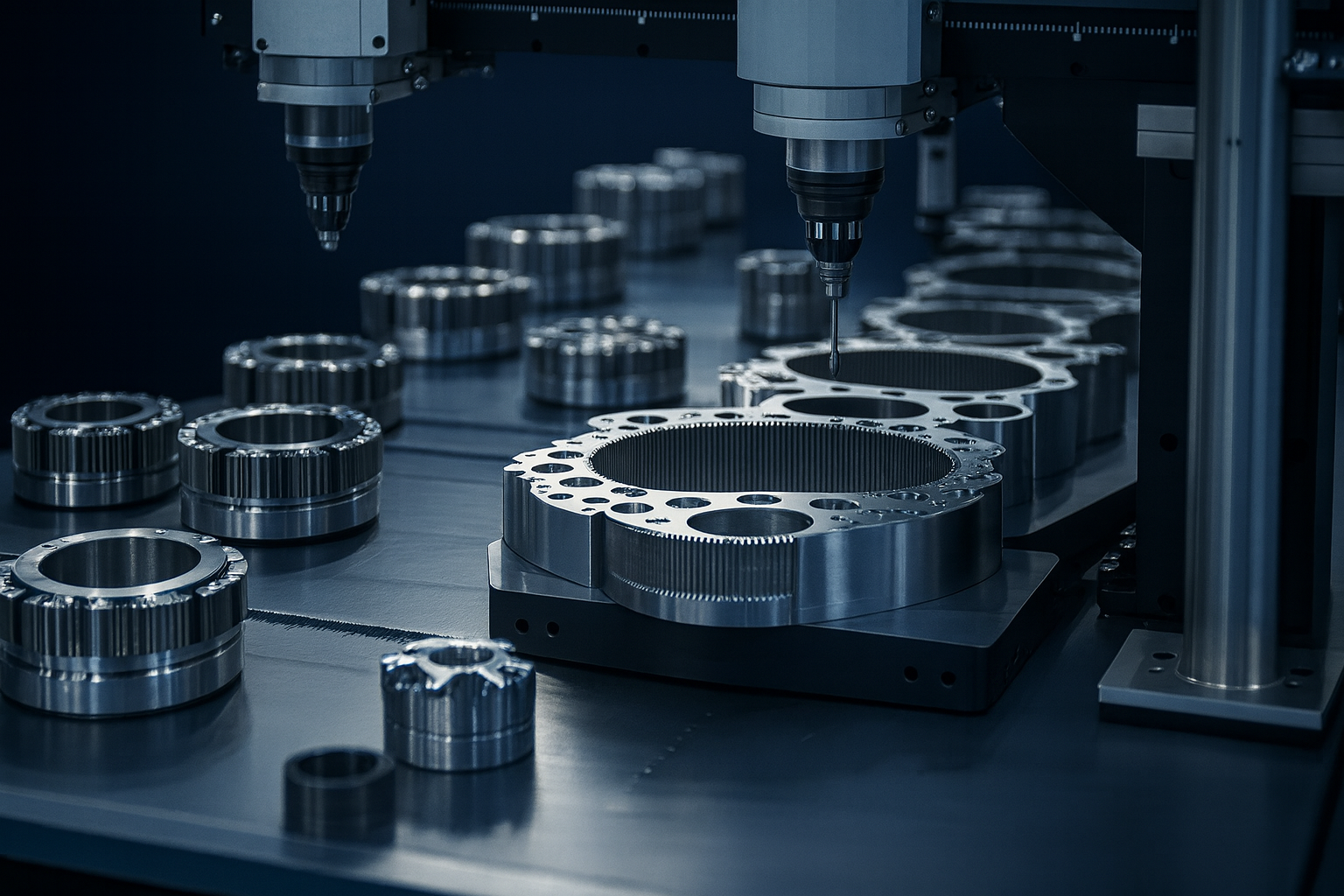

CNC Milling (3-Axis & 4-Axis)

High-precision milling for components that demand complex contours, tight tolerances, and excellent surface integrity. Our 3-axis

and 4-axis capabilities efficiently machine intricate geometries, multi-sided parts, and profile-intensive components such as

brackets, housings, manifolds, and mounting structures.

Each part is produced using optimized cutting strategies, controlled tool paths, and strict dimensional checks to ensure consistency

and repeatability across batches.

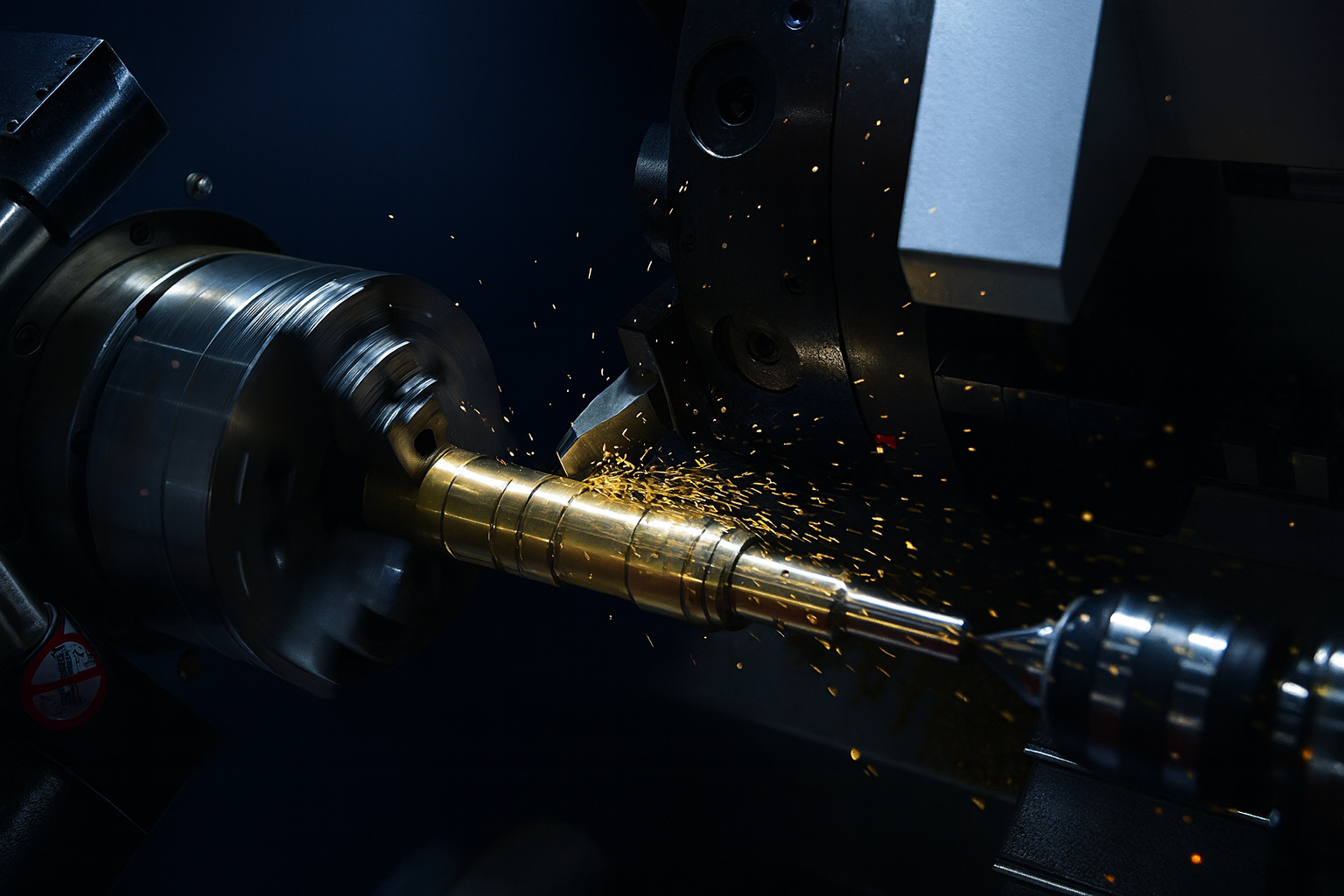

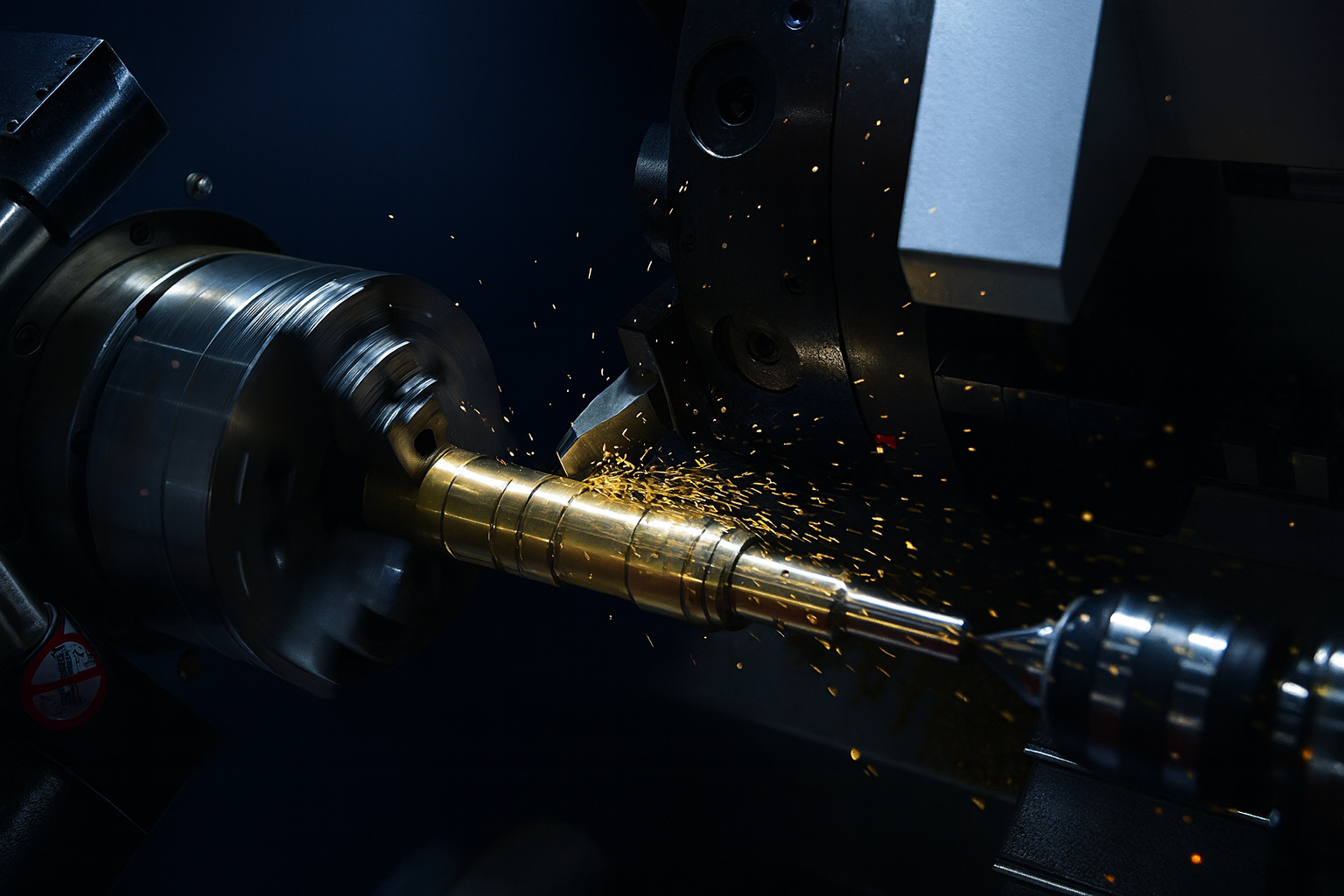

CNC Turning (High-Speed Lathe)

Accurate, repeatable cylindrical components including shafts, bushings, spacers, sleeves, and threaded parts. Stable setups, precision

tooling, and optimized cutting parameters deliver smooth surface finishes and tight diameter control.

This ensures reliable fitment, proper mechanical strength, and long-term performance in real-world assembly conditions.

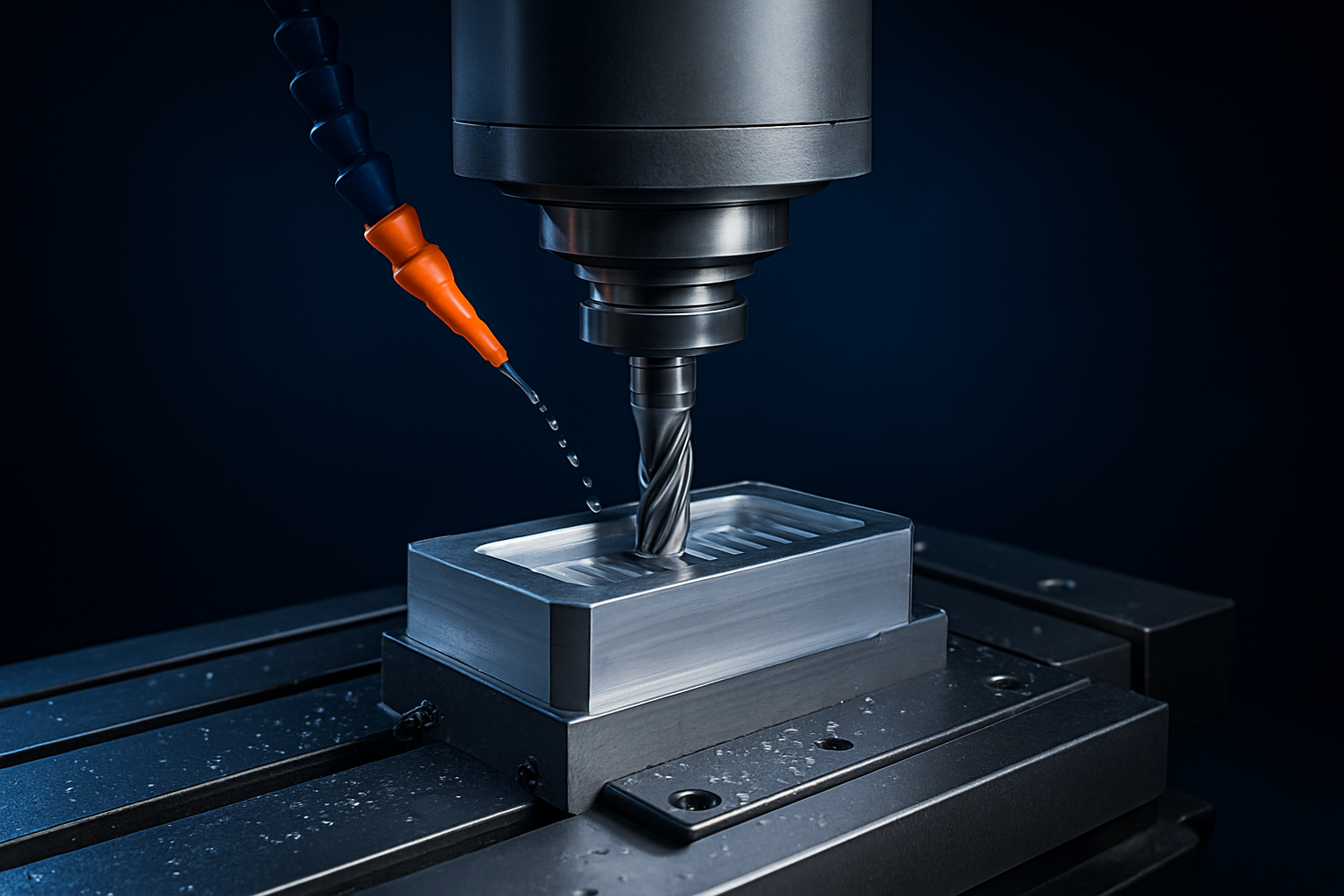

Production (VMC)

Medium to high-volume production on robust VMC platforms—designed for process stability, cycle-time efficiency, and consistent

dimensional accuracy across large batches.

Structured workflow planning, tooling control, and inspection intervals enable dependable output for OEM and industrial supply needs.

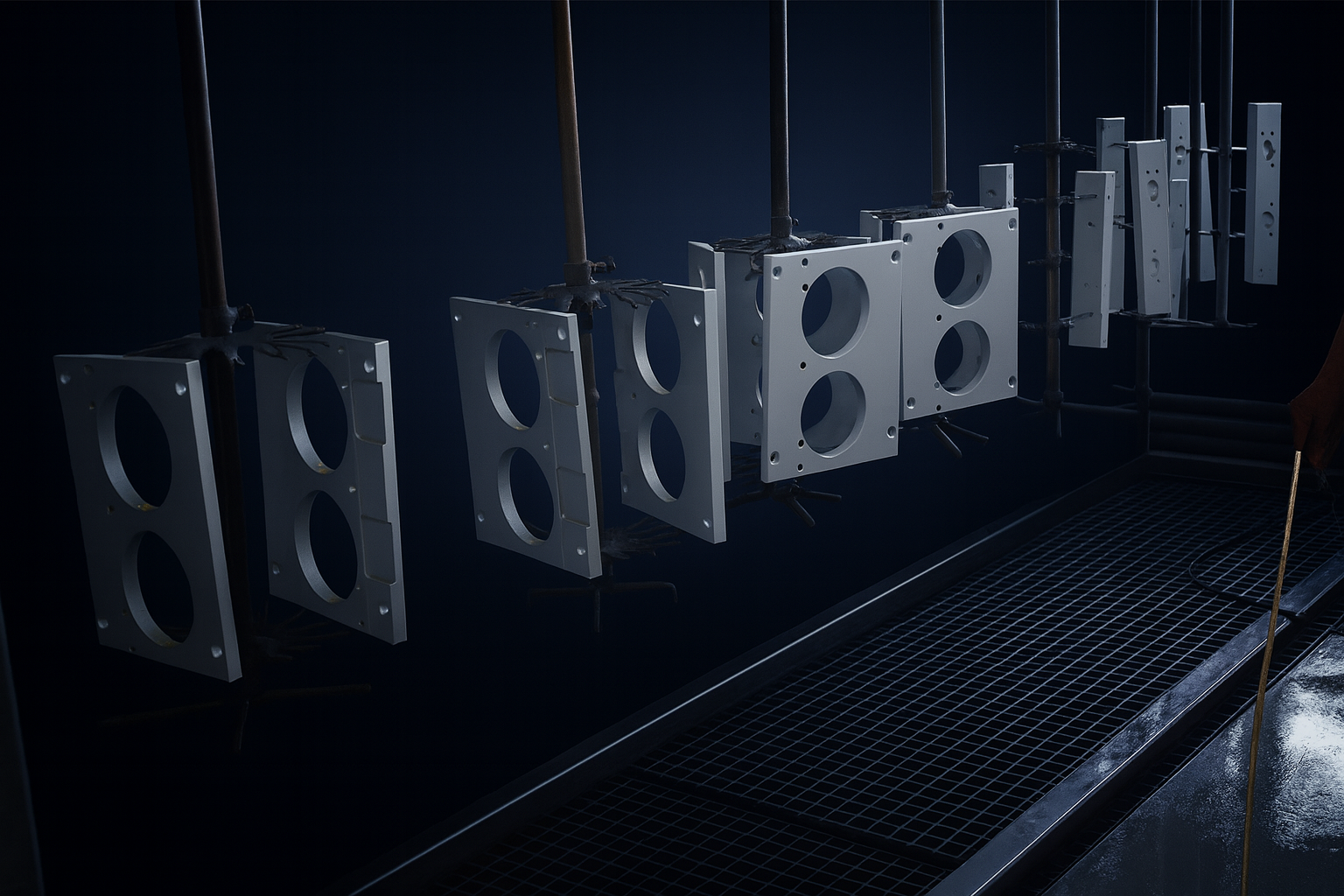

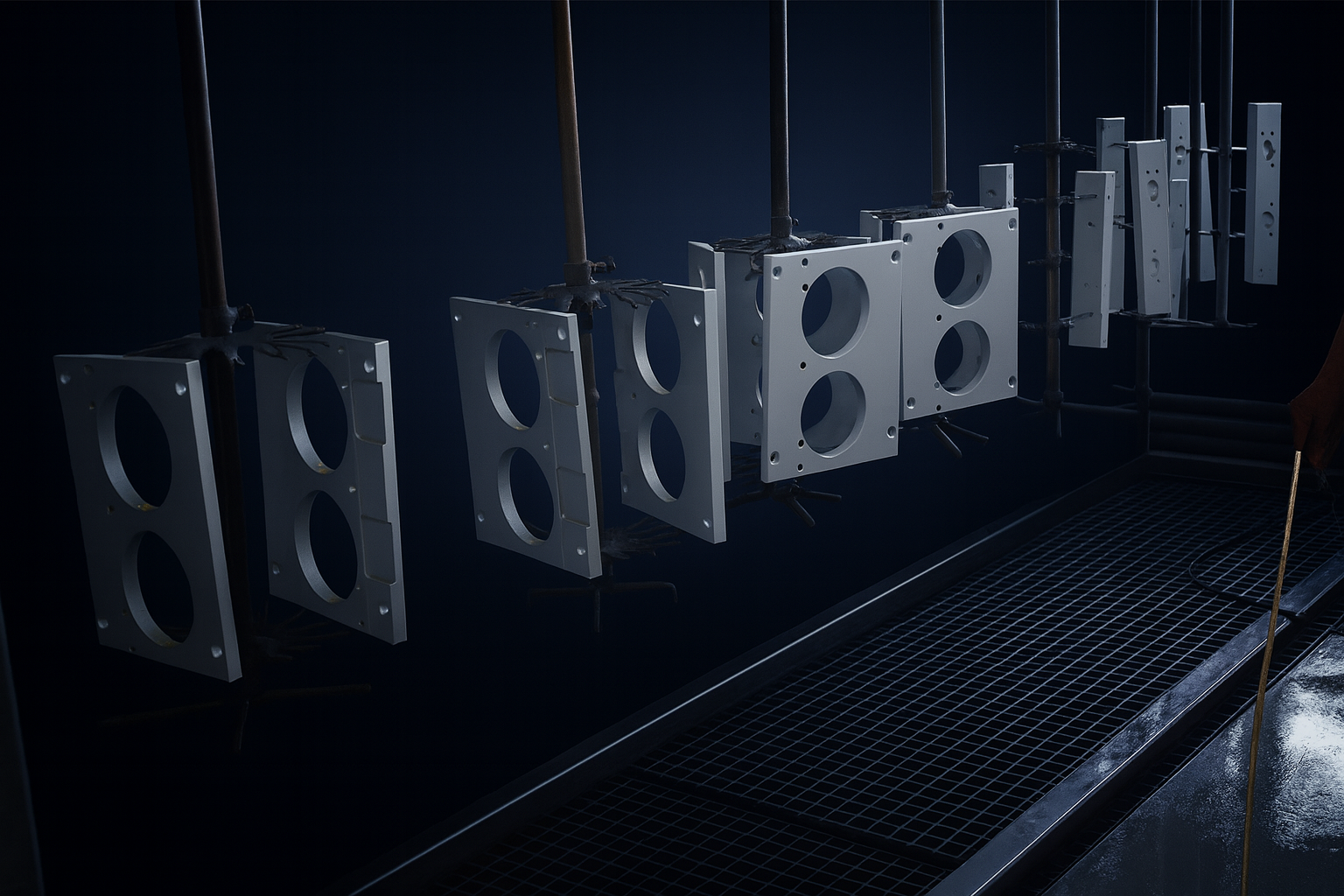

Secondary & Post-Processing

We offer complete post-machining and finishing solutions to deliver fully functional, application-ready parts. Our secondary services include anodizing, heat treatment, plating, grinding, welding, polishing, lapping, and assembly.

By managing these operations through trusted in-house and controlled partner processes, we ensure enhanced surface properties, improved wear resistance, corrosion protection, and precise mechanical performance.

Quality & Traceability Support

Quality control is integrated at every stage. We perform in-process and final inspections with precision instrumentation (including 2D

height gauges) and maintain material traceability via verified heat number tagging.

This ensures accountability, compliance with customer drawings, and consistent repeatability across every production batch.